The product portfolio is divided into three different groups: basecoats, topcoats, and thinners.

1. PRODUCT INFORMATION

The portfolio contains various product groups, organized by naming, delivery form, and labeling. The long term storage of the dip spin tanks is carried out according to regulations.

The most important function of the basecoats is to provide the coated steel surface with active protection against corrosion. This protective action is based on the sacrificial characteristic of zinc which is present in all basecoats.

A metal that is more anodic has a higher tendency to be subject to corrosion (i.e. "rust"). In comparison with iron and steel, zinc is very anodic. As a consequence, zinc will corrode first under unfavorable environmental conditions when in direct contact with iron and steel.

Corrosion is an electro-chemical process during which the metal involved in the reaction will be subject to oxidation. If the oxidizing metal is electroconductively connected to another metal, the electrons released from the anodic metal (in this case zinc) during oxidation flow to the more cathodic metal (in this case steel). This is where the terms "sacrificial anode" (i.e. zinc corrodes) and "cathodic corrosion protection" (steel is protected) originate from.

| Element | Mg | Al | Zn | Fe | Ni | Cu | Ag | Pt | Au |

|---|---|---|---|---|---|---|---|---|---|

| Standard potential E° (V) | -2.37 | -1.66 | -0.76 | -0.44 | -0.25 | 0.34 | 0.80 | 1.20 | 1.50 |

With a topcoat various properties of the coating system can be achieved:

- Setting a defined coefficient of friction;

- Sealing of surfaces;

- Resistance to chemicals;

- Abrasion resistance;

- Color

Applying a topcoat can significantly increase the durability of the underlying basecoat.

To adjust the paint to its ideal processing viscosity or for thinning, there are specific Dörken thinners for each paint. Each paint tolerates only these specific thinners. The use of unauthorized thinners voids the product warranty.

Numbers and lubricant information are added to the registered product names DELTA®-TONE, DELTA®-SEAL and DELTA-LUBE® for an exact identification of the product. The DELTA-PROTEKT® series products are clearly designated by letter combinations and a sequence of numbers:

The first two letters have the following meanings:

- K: Cathodic corrosion protection

- V: Sealing

- M: Modifier

- L: Solvent-based/solvent

- H: Water-based

The subsequent numbers indicate the functional system to which the product belongs. For products that contain a lubricant additive, the letters "GZ" are added to the product name.

EXAMPLES BASED ON SELECTED PRODUCTS

- DELTA-PROTEKT® KL 120: Zinc flake basecoat with cathodic protection, solvent based.

- DELTA-PROTEKT® VH 300: Inorganic water-based sealant.

- DELTA-PROTEKT® VH 301.1 GZ: Inorganic water-based sealant with lubricant additive.

Depending upon the type of product, different packaging containers are used, each of which ensures the best possible delivery quality and processability. Each order confirmation is accompanied by a certificate of inspection.

| The zinc flake basecoats and DELTACOLL® 80 GZ coatings are packaged in blue steel containers; the solvent-based topcoats are packaged in gray steel containers. |

|

| The clear water-based topcoats of the VH series and DELTA-LUBE® products are supplied in white plastic containers; pigmented, water-based topcoats are packaged in blue plastic containers. |

|

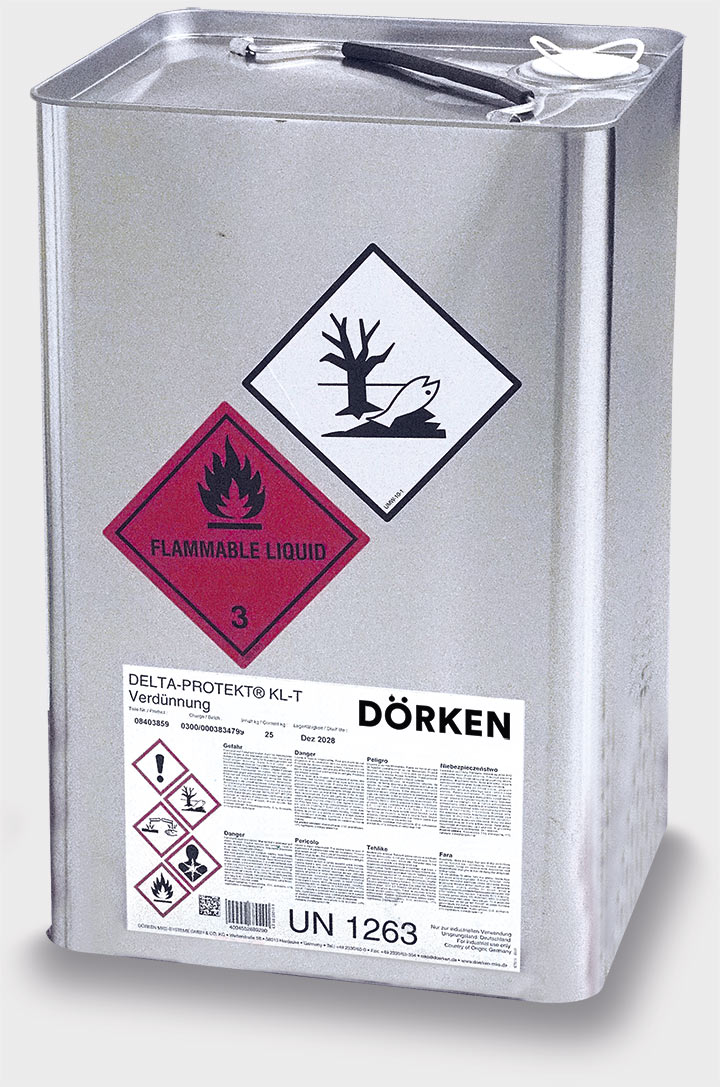

| Thinners and some products such as DELTACOLL® 80 are supplied in metal cans with a twist cap for easy use. |

|

Labels are attached to each material container. Safety labels and contents are subject to continuous changes and revisions...

- Product number

- Batch number

- Content quantity

- Shelf life

- Hazard information

- Safety instructions

- Contact details

For water-based products such as the VH series, a minimum storage temperature of 5 °C is recommended. Under no circumstances should the water-based products be stored below the freezing point.

As with all liquid coatings, elevated temperatures shorten the product shelf life as they have an effect similar to a premature, slow curing process. The increase in storage temperature leads to a slight but constant polymerization of the binding agent contained in the coating. The higher the temperature, the faster this process proceeds. It is therefore recommended to not store coating products above 35 °C. In general, a storage temperature of about 20–25 °C is ideal. In individual cases, the product technical data sheet should be considered.

Since zinc flake basecoats are highly sensitive to moisture, the product containers must always be tightly closed. If the product will not be used for several weeks, it is advised to seal the coating container airtight or return the material to the original containers.

If the temperature of the stored coating material is within the application range (e.g., 20–28 °C, note the dew point at the application site), rapid refilling of the coating tank is possible since no temperature adjustment is required.

Since zinc flake basecoats are highly moisture-sensitive, the containers must always be kept tightly closed. For longer pauses, seal the coating container airtight or return the material to the original container.

If the material remains in the tank, the gap between tank and lid should be sealed with a tear-resistant film.

For long-term storage, the following procedure is recommended:

| Process step | Control Parameters | Comment | |

|---|---|---|---|

| 1 | Immediately after the last coating cycle, remove the tank from the system | Homogeneous surface must be visible. If already in storage, homogenize first. No accumulation of thinner on the surface | no accumulation of thinner on the surface |

| 2 | Drain tanks into sealable, conductive empty containers (e.g., steel) via a filter | Evaluate filter residue according to internal specifications | e.g., delivery containers, 200 L barrels. Max fill 3/4 of total volume |

| 3 | Inspect all filled containers | Temperature, Viscosity, Solids | Ensure labeling: Product, fill date, container no., legally compliant. Adhesion/layer distribution, tape test: immerse cleaned sheet, remove immediately, allow 3 min to cure |

| Adhesion/layer distribution, tape test | immerse cleaned sheet, remove immediately, 3 min curing | ||

| 4 | Seal containers airtight | ||

| Clean tank and centrifugal ring/funnel of residues | |||

| 5 | Ensure storage conditions per technical data sheet | Lid must not bulge. Emergency vent possible with small hole and tape | |

| 6 | Mix and check containers fully with proper stirrer and dissolver disk | Temperature, Viscosity, Solids | Each container checked at start of storage |

| Adhesion/layer distribution, tape test | Adjust viscosity to storage viscosity. Immerse cleaned sheet, remove immediately, 3 min cure | ||

| 7 | Compare test parameters with Step 3 | Minor deviation in viscosity of 6s possible. All other parameters unchanged | |

| 8 | Fill tank at least 12h before production start and ensure homogenization | Only if Step 7 ok, otherwise consult Dörken | |

| 9 | Set viscosity immediately before production start | Viscosity, Temperature |

Filling containers

| Filling container | First container | Middle container | Last container | |||||

|---|---|---|---|---|---|---|---|---|

| Fill (Step 3) | Fill (Step 7) | Fill (Step 3) | Fill (Step 7) | Fill (Step 3) | Fill (Step 7) | |||

| Temperature | ||||||||

| Viscosity | ||||||||

| Solids | ||||||||

| Top: Layer thickness & Adhesion | Top | Layer thickness | ||||||

| Tape test | ||||||||

| Middle: Layer thickness & Adhesion | Middle | Layer thickness | ||||||

| Tape test | ||||||||

| Bottom: Layer thickness & Adhesion | Bottom | Layer thickness | ||||||

| Tape test |

Comments (0)

No comments yet.

Do you have constructive feedback?

Please log in to leave a comment.